![]()

MULTICAP

inspection machine for plastic and metal clousures

MULTICAP is the inspection machine for the control of aluminium and plastic closures.

The standard configuration includes three acquisition units: one for the inspection of the Border and the Liner, one for the inspection of the Top-printing (public side) and one special unit with six cameras for the inspection of the external sidewall.

Mechanical transportation

Depending on the inspection requirements we have different solution for the mechanical transportation system. In the most common case clousures are oriented with opening upward facing.

Border and Liner/Pourer inspection, which requires top views of the closure, can be performed either on a conveyor belt (with caps moving properly lined and spaced) or on a star-wheel. The solution on a star-wheel is preferred, because of the best precision and stability in the caps holding, required especially for the inspection of the border that uses a wide-angle lens.

Ejection is managed by a supervision unit (PLC), using an encoder installed on the star-wheel axis. In this case, it is possible to reject the defective closures anywhere, setting the proper number of encoder pulses respect to the sync signal (step signal of the star-wheel).

For all the inspections, the cap must be hold steadily in the pockets during the movement, avoiding oscillations.

Top-printing inspection

Top-Printing inspection requires a star-wheel transportation, where a bottom view is possible through a hole in the main plate while the cap is held in the star’s pocket by a rubber belt or slips on a special glass. This inspection cannot be performed on a belt because in this case the Top-Printing surface is not visible, being hidden by the belt.

Star-wheel and of the other mechanical parts (holding edges…) in the inspection area are “opaque black”, to avoid light reflections that can affect the quality of the images.

Border Inspection

For the Border inspection, the border must protrude some mm (min. 5 mm) from the top surface of the star-wheel and of the holding edges.

Sidewall inspection

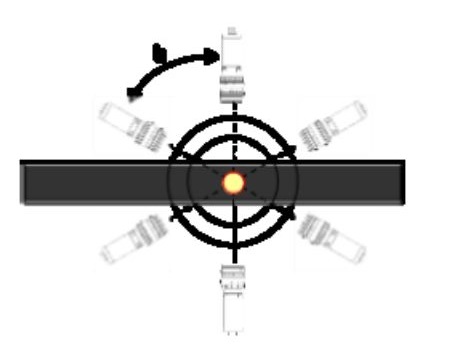

The inspection of the sidewall is performed with a six-colour cameras unit. The cameras, placed a 60° each other, observe all the lateral surface of the cap. The lighting system is a high intensity LEDs ring-light, designed to illuminate with high uniformity the external lateral surface of the closures. An additional light beam in the inside allows inspecting proper making of the closure, as for example the cutting.

After the acquisition of the images through the six views, the software reconstructs the complete horizontal development of the external lateral surface of the cap, aligning the edges of the six acquired images. For the mosaic only the central part of each 60° image is used, in order to limit the reduction of information in the part of images more distant from the optical axis. In any case, before joining and aligning the six images, a geometrical calibration is applied to each to correct the optical distortion.

Below the geometry of the sidewall standard unit, together with the six acquired images and the one resulting from the merging.