SPECTRO-G

Print Inspection on glass bottles

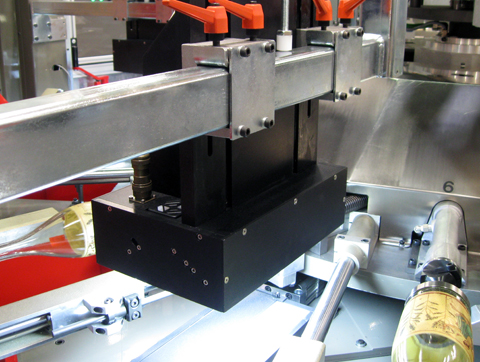

Spectro-G is designed to inspect the print on cylindrical and oval glass objects like bottles and drinking glasses.

Thanks to Spectro-G it is possible to detect the main printing problems generated by silk-screen and digital printing processes.

Benefits

Spectro guarantees a powerful combination of print quality and waste reduction. Objectivity and accuracy of the control improve your print quality and it ensures a production without printing defects.

On line integration allows waste reduction and printing process optimization. Spectro is able to prevent widespread failure and averts large quantities of waste.

The benefit results in cost reduction and improved process efficiency that drives up profits and company reputation.

Quality is easy

Spectro can easily be installed into all printing machines. Our highly qualified engineers are able to design the best solution that fits any integration need.

Spectro is easy to use: the setup of a new job can be done and saved for future use in less than one minute.

No special knowledge is required.

Different configurations for different needs

Three standard configurations are available but it is possible to customize the system integration depending on customer application or

special requirements.

Thousands of successfully installations make the Spectro system your ideal partner.

SPECTRO-G150 controls the decoration (silk-screen or pad-printing) on glass, as flacons, jars and small bottles. Spectro-G detects all typical defects of the printing process and it can also check the decoration on rotating cylindrical objects and on plane surfaces.

Spectro-G 150 can be directly installed on the printing machine and it can assure a production quality up to 150 pieces/min. There are two available models: one is equipped with grey-level camera and the other one with colour camera. The field of view is 150 mm.

SPECTRO-G250 checks the printed decoration on cylindrical objects like bottles and glass.

Spectro detects all typical problems of the screen printing.

The software inspects the decoration on rotating objects without any index and it automatically centers the image of the checked object compared to the reference model.

Spectro can be installed directly on the printing machine and can assure a speed up to 150 pieces/min.

SPECTRO-G350 checks the printed decoration on cylindrical objects like bottles and glass.

Spectro detects all typical problems of the screen printing.

The software inspects the decoration on rotating objects without any index and it automatically centers the image of the checked object compared to the reference model.

Spectro can be installed directly on the printing machine and can assure a speed up to 100 pieces/min.